This article belongs to the field of forging,and specificallyrelates to a method,device and process for producing large forginc

blanks in a large forging factory in China.The function of adjusting the cross-sectional area and shape of the blank to meet the

requirements of die forging.

Large-scale forging factory in China.

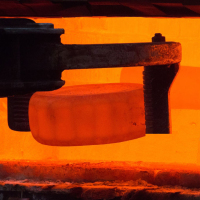

In the forging production process of large forging plants in Chinain order to obtain high-quality forgings and maximize

material utilization and die life,large forging plants in China will carry out some blanking work according to the structure and

shape of the product,so that the metal material can be reasonably obtained.allocation.However,for large forgings, due to the large size of the blank,these blank making processes cannot beimplemented on the die,especially for the blank with a

diameter greater than 200mm,there is no corresponding specification at present.If free forging equipment is used to make

billets, the skills of workers are high and the processing efficiency is low.

China's large-scale forging factory provides a large-scale forging blanking device and its use method.The device has simple

structure and convenient operation,can efficiently complete the process of upsetting and bending blanks at both ends or one

end of the blank.and meets the reauirements of die foraina.The technicasolutions adopted byarae foraina factories in China

are as follows:

The method for foraina blanks in a larae foraina factorv in China includes the followina steps: placina the movable lower die at

the discharge position on the worktable, passing through the two grooves at the lower part of the movable lower die through

the quide rails on the worktable,and placing the movable lower die on the worktable.The die is connected with the piston end

of the die-moving cylinder; according to the process requirements,the large forging factory in China can adjust the size of the

positioning bolt on the positioning bolt fixing frameso that the accurate axial positioning of the blank during production car

be obtained; the large forging factory in China makes the axial upsetting The piston of the rough cylinder is retracted,the

upper mold is placed on the moving lower moldthe mold transfer cylinder is activated,the piston of the mold transfer cylinder drives the lower mold and the upper mold to move to the workina position. and the compression mold cvlinder is activated to

make the piston of the compression mold cylinder and the upper mold move to the working position.The upper surface of the

upper die is contacted and fixed downward; the piston of the die cylinder is returned upward,and the upper die is moved to

the upper dead center position, so that the piston of the die-moving cylinder drives the moving lower die to return to the

discharging position;the die-moving cylinder is activated,The piston of the die-moving cylinder drives the moving lower die and the material section to the working position; starts the molding cylindermoves the upper die downward,compresses the

material section,and closes the upper die with the moving lower die;starts the shaft of a large forging factory in China To the

upsetting cylinder,the two ends of the material section are upset and deformed,and the whole deformation process is

completed the piston of the axial upsetting cylinder drives the upsetting die to return,and the molding cylinder drives the

upper die to return to the upper dead center,so that the moving The piston of the die cylinder pushes the lower die to return

to the discharge positionand the upsetting and deformed material section is removed.

For products with upsetting blanks at one end,one end of the die can be closed for axial positioning.For press-bending blanks

the upper die and the movable lower die are cavities with a press-bendina structure.After the movable lower die reaches the

working position,the clamping cylinder that starts the clamping moves the upper die downward to realize the bending action

of the blank until the clampina cvlinder stops.so that the clampina cvlinder drives the upper die back to the upper die. At the

point, the piston of the die-moving cylinder pushes the movable lower die back to the discharge position, and removes the

deformed material section.

The advantages of the products produced by the above-mentioned large-scale forging factories in China are: the process of

upsetting and bending blanks at both ends and one end of the forgings can be completed,and the cross-sectional area of the

blanks can be quickly adiusted to meet the requirements of die forging.