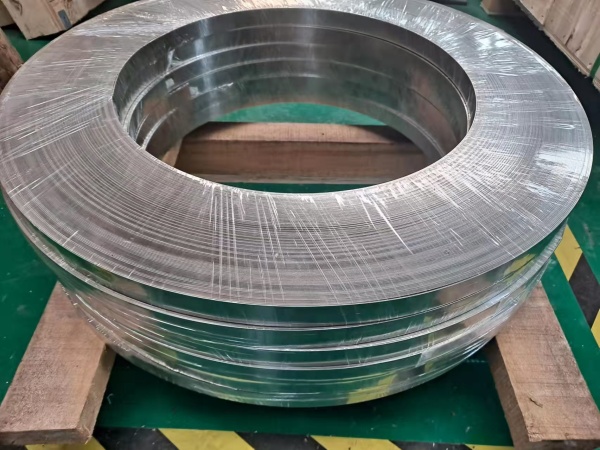

Hangbo Alloy Group supplies a comprehensive range of INCONEL 617 alloy products, including round bars, plates, strips, seamless tubes, forgings, and wires. Below is a detailed overview of INCONEL 617.

Introduction to INCONEL 617

INCONEL 617 (UNS N06617) is a nickel-chromium-cobalt-molybdenum alloy renowned for its outstanding combination of high-temperature strength and oxidation resistance. It maintains excellent weldability and resistance to a wide range of corrosive environments, making it highly reliable in severe operating conditions.

- International Equivalents:

- USA: UNS N06617

- Europe: DIN 2.4663

Standards for INCONEL 617 Products

- Plates: ASTM B168, ASME SB-168

- Round Bars: ASTM B166, ASME SB-166

- Seamless Tubes: ASTM B167, DIN 2.4663

- Forgings: AST

Chemical Composition of INCONEL 617 (in Vertical Table) M B564, ASME SB-564

| Element | Content (%) |

|---|---|

| Nickel (Ni) | ≥44.5 |

| Chromium (Cr) | 20.0 - 24.0 |

| Cobalt (Co) | 10.0 - 15.0 |

| Molybdenum (Mo) | 8.0 - 10.0 |

| Iron (Fe) | ≤ 3.0 |

| Copper(Cu) | ≤ 0.5 |

| Aluminum (Al) | 0.8 - 1.5 |

| Titanium(Ti) | ≤ 0.60 |

| Carbon (C) | 0.05-0.15 |

| Manganese (Mn) | ≤1.0 |

| Silicon (Si) | ≤ 1.0 |

| Sulfur (S) | ≤ 0.015 |

| Boron(B) | ≤ 0.006 |

Physical Properties of INCONEL 617

| Property | Value |

|---|---|

| Density | 8.36 g/cm³ |

| Melting Range | 1335-1380 °C |

Material Characteristics of INCONEL 617

- Oxidation and Carburization Resistance: Excellent resistance to oxidation and carburization at temperatures up to 1100°C.

- Mechanical Strength: Maintains high mechanical strength and creep resistance at elevated temperatures, enhancing durability.

- Corrosion Resistance: High resistance to various acidic and basic environments, making it reliable in extreme corrosive conditions.

- Fabricability: Good weldability and workability, allowing for versatility in fabrication.

- Thermal Stability: Exceptional structural stability in high-temperature applications, reducing risk of degradation over time.

Applications of INCONEL 617

- Gas Turbines: Used in combustion cans, ducting, and transition liners due to its high-temperature and oxidation resistance.

- Chemical Processing: Ideal for use in reactor vessels and piping exposed to corrosive chemicals.

- Petrochemical and Refinery: Suitable for components in sulfur-rich environments and high-temperature processing.

- Nuclear Power: Utilized in high-temperature reactor systems, where material stability is critical.

- Industrial Heating: Applied in furnace components and radiant tubes that endure extreme temperatures.