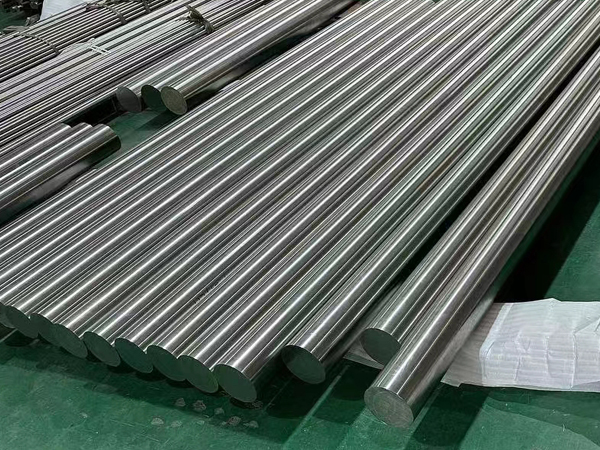

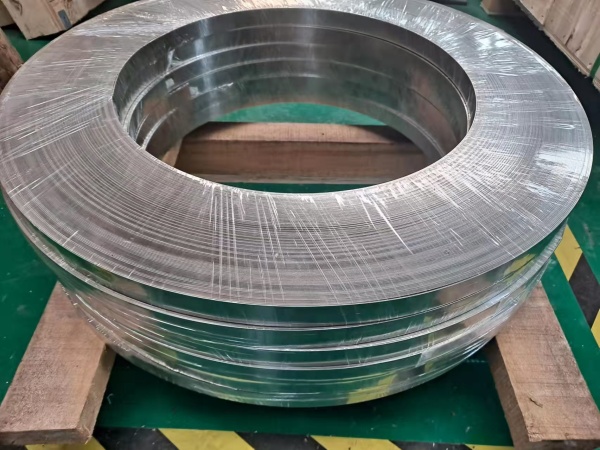

Hangbo Alloy Group supplies a comprehensive range of INCONEL 718 alloy products, including round bars, plates, strips, seamless tubes, forgings, and wires. Below is a detailed description of INCONEL 718.

Introduction to INCONEL 718

INCONEL 718 (UNS N07718) is a nickel-chromium alloy known for its excellent combination of high tensile, fatigue, creep, and rupture strength. This age-hardenable alloy is designed to withstand extreme temperatures, up to 700°C, making it ideal for applications in aerospace, nuclear power, and oil and gas industries.

- International Equivalents:

- USA: UNS N07718

- Europe: DIN 2.4668

- China: GH4169

Standards for INCONEL 718 Products

- Plates: ASTM B670, ASME SB-670

- Round Bars: ASTM B637, ASME SB-637

- Seamless Tubes: ASTM B163, ASTM B407, DIN 2.4668

- Forgings: ASTM B637, ASME SB-637

- Wires: ASTM B666

Chemical Composition of INCONEL 718 (in Vertical Table)

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 50.0 - 55.0 |

| Chromium (Cr) | 17.0 - 21.0 |

| Iron (Fe) | Bal. |

| Molybdenum (Mo) | 2.80 - 3.30 |

| Niobium (Nb) | 4.75 - 5.50 |

| Titanium (Ti) | 0.65 - 1.15 |

| Aluminum (Al) | 0.20 - 0.80 |

| Cobalt (Co) | ≤ 1.00 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

| Copper (Cu) | ≤ 0.30 |

| Boron (B) | ≤ 0.006 |

Physical Properties of INCONEL 718

| Property | Value |

|---|---|

| Density | 8.19 g/cm³ |

| Melting Range | 1260-1336 °C |

Material Characteristics of INCONEL 718

- High Strength and Durability: INCONEL 718 has excellent mechanical properties, including high tensile, creep, and rupture strength, maintained up to 700°C. This makes it ideal for heavy-duty applications in aerospace and industrial sectors.

- Corrosion Resistance: It exhibits remarkable resistance to oxidation and corrosion in a wide range of environments, including those containing acids and salts.

- Weldability: INCONEL 718 is easily weldable, without the risk of cracking, which is often a challenge with other high-strength superalloys.

- Age-Hardenable: The alloy can be hardened by heat treatment, allowing for customization of mechanical properties depending on specific application requirements.

Applications of INCONEL 718

- Aerospace: Used extensively in aircraft engines, turbine blades, and other components subjected to extreme heat and mechanical stress.

- Nuclear Power: Ideal for use in steam generators and other high-temperature components in nuclear power plants.

- Oil & Gas: Commonly used in downhole shafts, wellhead components, and other high-performance parts due to its strength and corrosion resistance.

- Industrial Gas Turbines: Utilized in components like combustion chambers, transition ducts, and turbine seals, which experience high heat and cyclic loading.

- Chemical Processing: Suitable for equipment exposed to corrosive environments, such as reactor vessels and heat exchangers.