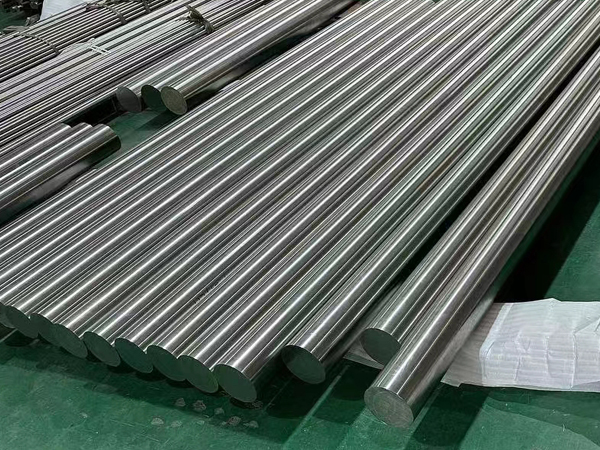

Hangbo Alloy Group supplies a comprehensive range of INCONEL X-750 alloy products, including round bars, plates, strips, seamless tubes, forgings, and wires. Below is a detailed description of INCONEL X-750.

Introduction to INCONEL X-750

INCONEL X-750 (UNS N07750) is a precipitation-hardenable nickel-chromium alloy known for its excellent high-temperature performance and resistance to corrosion and oxidation. This alloy retains its strength and stability up to 704°C (1300°F) and is frequently used in aerospace, nuclear, and gas turbine applications.

- International Equivalents:

- USA: UNS N07750

- Europe: DIN 2.4669

- China: GH4145

Standards for INCONEL X-750 Products

- Plates: ASTM B670, ASME SB-670

- Round Bars: ASTM B637, ASME SB-637

- Seamless Tubes: ASTM B163, ASTM B407, DIN 2.4669

- Forgings: ASTM B637, ASME SB-637

- Wires: ASTM B639

Chemical Composition of INCONEL X-750 (in Vertical Table)

| Element | Content (%) |

|---|---|

| Nickel (Ni) | ≥70.0 |

| Chromium (Cr) | 14.0 - 17.0 |

| Iron (Fe) | 5.0 - 9.0 |

| Titanium (Ti) | 2.25 - 2.75 |

| Aluminum (Al) | 0.40 - 1.00 |

| Niobium (Nb) | 0.70 - 1.20 |

| Cobalt (Co) | ≤ 1.00 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.010 |

| Copper (Cu) | ≤ 0.50 |

Physical Properties of INCONEL X-750

| Property | Value |

|---|---|

| Density | 8.28 g/cm³ |

| Melting Range | 1393-1427 °C |

Material Characteristics of INCONEL X-750

- High-Temperature Strength: INCONEL X-750 maintains its strength and stability in high-temperature environments, withstanding up to 704°C, which makes it ideal for demanding aerospace and power applications.

- Corrosion and Oxidation Resistance: This alloy is highly resistant to oxidation and corrosion, even under extreme temperatures, and is suitable for use in environments containing acidic and saline elements.

- Good Fabricability: The alloy offers ease in fabrication, including welding and forming, which allows it to be used in a variety of industrial applications.

- Long-Term Stability: INCONEL X-750 demonstrates excellent creep-rupture strength, making it a reliable choice for long-term performance in elevated-temperature conditions.

Applications of INCONEL X-750

- Aerospace: Widely used in turbine blades, rocket engines, and other high-temperature components within the aerospace industry.

- Nuclear Power: Commonly applied in reactor core components, control rods, and other parts due to its ability to withstand radiation and high temperatures.

- Gas Turbines: Used in components such as combustion chambers, transition liners, and other parts exposed to extreme temperatures.

- Industrial Heating: Suitable for furnace components and radiant tubes, where it resists oxidation and maintains strength.

- Automotive: Employed in exhaust valves and other automotive components that endure high heat and corrosive gases.