Hangbo Alloy Group supplies a comprehensive range of INCONEL 625 alloy products, including round bars, plates, strips, seamless tubes, forgings, and wires. Below is a detailed description of INCONEL 625.

1. Introduction to INCONEL 625

Description:Inconel 625 is a premium nickel-based super alloy, distinguished by its exceptional combination of mechanical strength, corrosion resistance, and thermal stability.In high - temperature environments, Inconel 625 maintains remarkable strength and stability. It can endure temperatures up to 982°C (1800°F) while still retaining its mechanical properties, which is crucial for applications in aerospace, gas turbines, and industrial furnaces

International Equivalents:

USA: UNS N06625

Europe: DIN 2.4856

China: GH3625

2. Standards for INCONEL 625 Products

Plates: ASTM B443,EN10088-2

Round Bars: ASTM B446,DIN 17752

Seamless Tubes: ASTM B444,ASTM B163,DIN17753

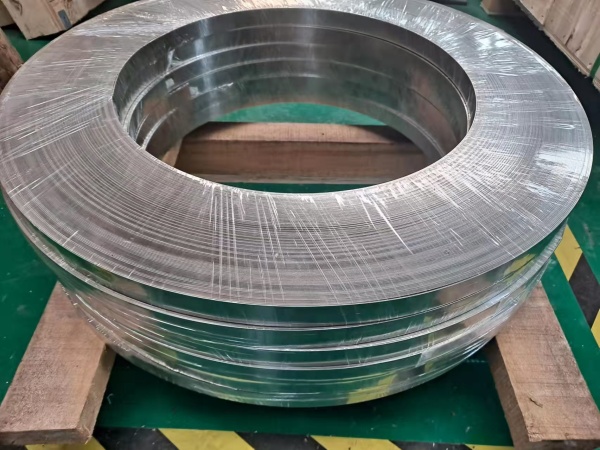

Forgings: ASTM B564, EN 10228-7

Wires: ASTM B446 ,AMS 5837

3. Chemical Composition of INCONEL 625

| Element | Content (%) |

|---|---|

| Nickel (Ni) | ≥ 58.0 |

| Chromium (Cr) | 20.0 - 23.0 |

| Iron (Fe) | ≤ 5.0 |

| Titanium (Ti) | ≤ 0.4 |

| Aluminum (Al) | ≤ 0.4 |

| Niobium (Nb)+Tantalum(Ta) | 3.15-4.15 |

| Molybdenum(Mo) | 8.0-10.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

4. Physical Properties of INCONEL 625

| Property | Value |

|---|---|

| Density | 8.44g/cm³ |

| Melting Range | 1290-1350 °C |

5. Material Characteristics of INCONEL 625

Excellent Corrosion Resistance: Inconel 625 exhibits strong resistance to various corrosive media, including seawater, acidic solutions, and alkaline environments. It can resist pitting, crevice corrosion, intergranular corrosion, and stress corrosion cracking, making it suitable for long-term use in harsh corrosive environments.

Outstanding High-Temperature Performance:The alloy maintains high creep strength and fatigue resistance at elevated temperatures (up to 980 °C). Its stable microstructure under high temperatures ensures reliable performance in long-term high-temperature service scenarios.

Good Fabrication and Welding Properties:Inconel 625 is adaptable to both cold and hot forming processes, enabling the production of complex-shaped components. It also has excellent welding performance, and welded joints retain good mechanical properties and corrosion resistance without significant performance degradation.

6. Applications of INCONEL 625

Aerospace:It is used in the manufacturing of aero-engine combustion chamber liners, turbine blades, and rocket nozzles. Its high-temperature resistance and corrosion resistance meet the strict performance requirements of aerospace components under extreme working conditions.

Marine Engineering:In marine engineering, it is applied in seawater pipelines, propeller blades, and deep-sea detectors. Its strong resistance to salt spray corrosion ensures the long-term service life and reliability of marine equipment.

Chemical and Energy Industries:In the chemical industry, it is used to make reactors, heat exchangers, and flue gas desulfurization systems. In the energy sector, it is utilized in nuclear fuel components and oil and gas well drilling equipment, thanks to its corrosion resistance and high-temperature stability.

Automotive Industry: It is employed in automotive exhaust systems and oxygen sensor springs. It can withstand high temperatures from exhaust gases and resist corrosion from harmful gases, while also meeting the lightweight requirements of automotive components.