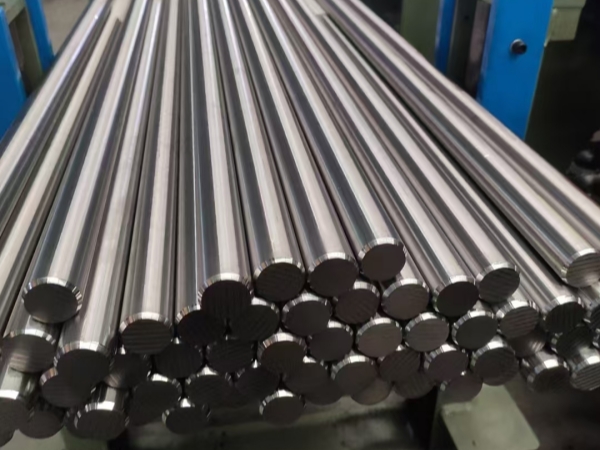

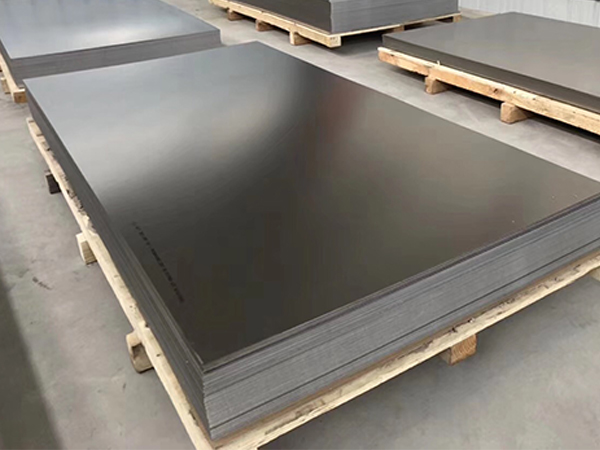

Hangbo Alloy Group offers a diverse range of materials, including round bars, steel plates, strips, seamless pipes, forged products, wire and fittings. Below is a comprehensive overview of HASTELLOY C-4:

Detailed Introduction to Hastelloy C-4

Hastelloy C-4 is a nickel-chromium-molybdenum alloy recognized for its exceptional resistance to corrosion, particularly in extreme environments. It is designed to withstand a variety of corrosive media, including both reducing and oxidizing conditions, making it suitable for a wide range of chemical processing applications.

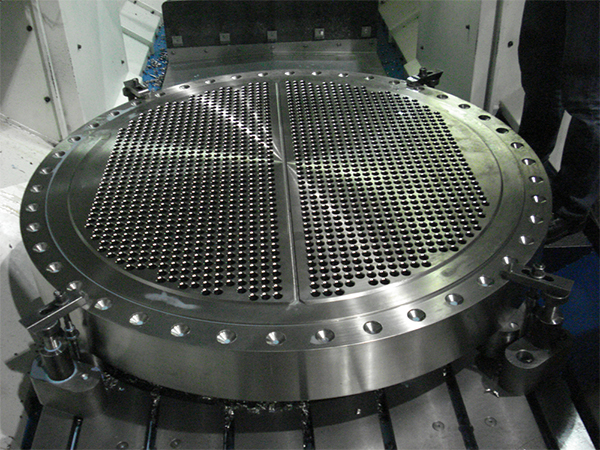

Hastelloy C-4's alloy composition provides superior resistance to stress corrosion cracking and localized corrosion, such as pitting and crevice corrosion. It also demonstrates excellent weldability and fabricability, allowing it to be easily formed into different shapes and structures, which enhances its versatility in industrial applications.

Equivalent Grades by Country:

• ASTM: UNS N06455

• DIN: NiCrMo-4 W.Nr.2.4610

International Standards for Hastelloy C-4 Products

The following table outlines the applicable standards for Hastelloy C-4 in various forms:

| Product Form | ASTM Standard |

|---|---|

| Plate,Sheet&Strip | ASTM B575 |

| Round Bar | ASTM B574 |

| Seamless Pipe&Tube | ASTM B622 |

| Welded Pipe&Tube | ASTM B619, ASTM B626 |

| Fittings | ASTM B366 |

Chemical Composition of Hastelloy C-4

The chemical composition of Hastelloy C-4 is summarized in the following table:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 58.2-72.0 |

| Chromium (Cr) | 14.0-18.0 |

| Molybdenum (Mo) | 14.0-17.0 |

| Iron (Fe) | ≤ 3.0 |

| Cobalt(Co) | ≤2.00 |

| Titaniun(Ti) | ≤ 0.70 |

| Carbon (C) | ≤ 0.015 |

| Silicon (Si) | ≤ 0.08 |

| Manganese (Mn) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

Physical Properties of Hastelloy C-4

Key physical properties of Hastelloy C-4 are outlined in the table below:

| Property | Value |

|---|---|

| Density | 8.64 g/cm³ |

| Melting Point | 1370 - 1425 °C |

Material Characteristics

Hastelloy C-4 is characterized by several key properties:

• Corrosion Resistance: Exceptional resistance to a wide range of corrosive media and environments.

• Localized Corrosion Resistance: Superior protection against pitting, crevice corrosion, and stress corrosion cracking.

• Weldability: Good weldability enables the alloy to be easily fabricated into various shapes without compromising performance.

• High-Temperature Strength: Maintains mechanical properties at elevated temperatures.

Applications of Hastelloy C-4

Hastelloy C-4 is widely utilized across several industries, including:

• Chemical Processing: Equipment and components for handling corrosive chemicals.

• Pharmaceuticals: Applications in drug manufacturing that require high purity and resistance to corrosion.

• Oil and Gas: Used in offshore applications and other environments where resistance to corrosion is critical.

• Environmental Protection: Equipment for flue gas desulfurization and related technologies to control emissions.