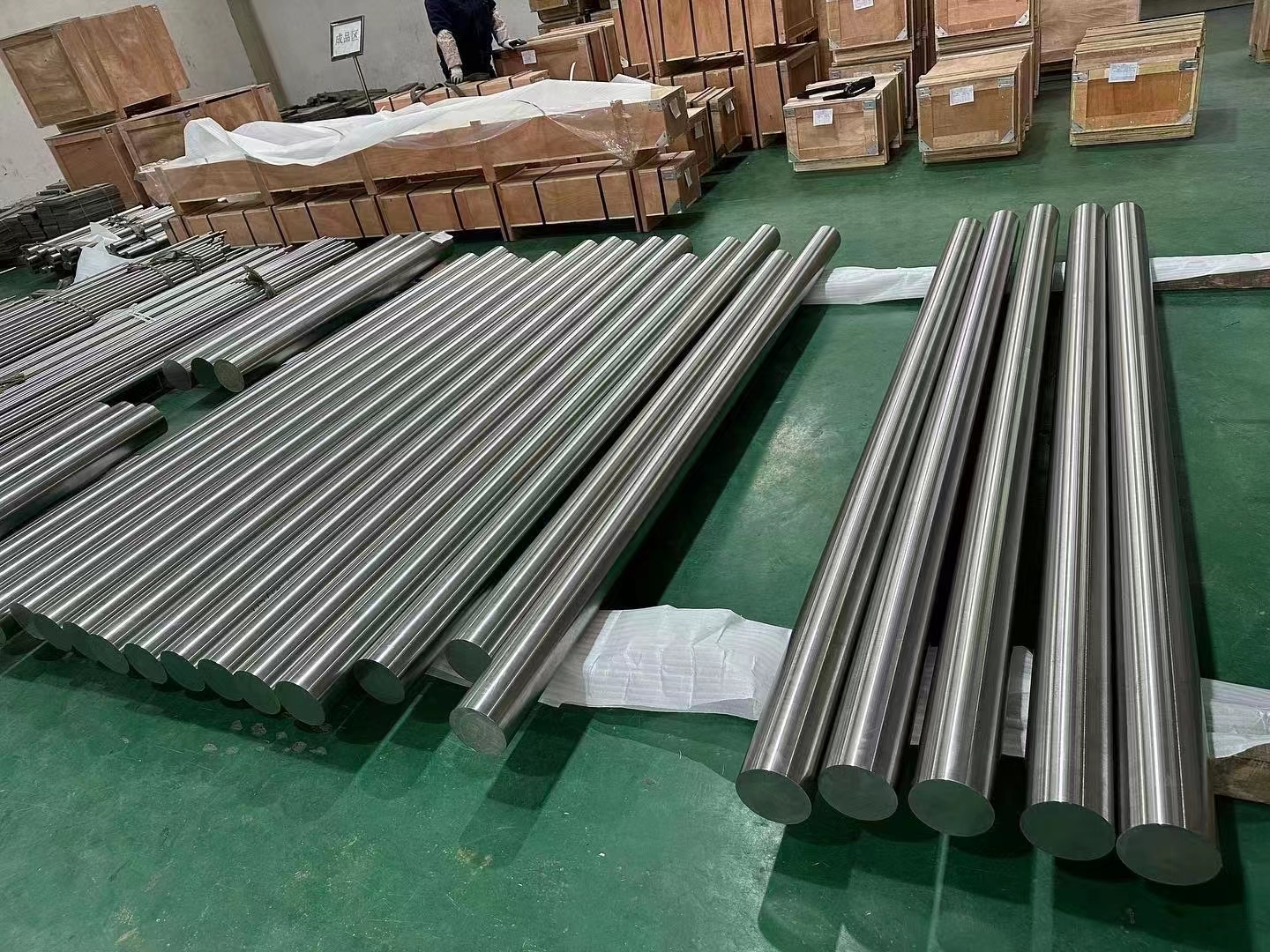

Hangbo Alloy Group offers a comprehensive range of high-performance alloy products, including round bars, plates, strips, seamless pipes, forgings, and wires. Among these, Nimonic 80A is a prominent nickel-based superalloy designed for excellent strength, oxidation resistance, and high-temperature performance.

Nimonic 80A is an age-hardenable alloy with controlled additions of titanium, aluminum, and carbon to ensure outstanding creep and fatigue resistance. Originally developed for use in high-temperature gas turbines, it is now widely used across various demanding industrial sectors.

Equivalent Designations in Different Standards

| Standard | Equivalent Designation |

|---|---|

| UNS | N07080 |

| W.Nr (Germany) | 2.4952 |

| ISO | NiCr20TiAl |

Product Forms and Standards

Hangbo Alloy Group provides Nimonic 80A in various forms, all meeting stringent international standards. The following table lists the applicable standards for each product type:

| Product Form | ASTM Standard |

|---|---|

| Round Bar | ASTM B637 |

| Plate/Sheet | ASTM B443 |

| Seamless Pipe | ASTM B622 |

| Forging | ASTM B637 |

Chemical Composition of Nimonic 80A

The alloy's composition is carefully designed to balance high-temperature strength and oxidation resistance. Here are the detailed chemical limits:

| Element | Composition (% by weight) |

|---|---|

| Nickel (Ni) | Remainder |

| Chromium (Cr) | 18.0 - 21.0 |

| Titanium (Ti) | 1.80 - 2.70 |

| Aluminum (Al) | 0.50-1.80 |

| Carbon (C) | ≤0.10 |

| Iron (Fe) | ≤3.0 |

| Manganese (Mn) | ≤1.00 |

| Sulfur (S) | ≤0.015 |

| Silcon(Si) | ≤1.00 |

Physical Properties of Nimonic 80A

| Property | Value |

|---|---|

| Density | 8.2 g/cm³ |

| Melting Point | 1350°C – 1380°C |

Key Characteristics of Nimonic 80A

High-Temperature Strength: Excellent creep and fatigue resistance at temperatures up to 815°C, making it ideal for use in extreme environments.

Oxidation Resistance: Performs well in high-temperature, oxidative environments, ensuring long-lasting reliability.

Age-Hardenable: Its strength can be enhanced through heat treatment for specific application requirements.

Corrosion Resistance: Good resistance to corrosion and oxidation in harsh conditions.

Ease of Fabrication: Despite its high strength, the alloy is readily machinable and weldable.

Applications of Nimonic 80A

Due to its unique properties, Nimonic 80A is extensively used in the following sectors:

Aerospace Industry: Turbine blades, discs, and other components in jet engines.

Power Generation: Steam turbines and high-temperature furnace components.

Automotive Industry: High-performance exhaust valves.

Chemical Processing: Heat exchangers and high-temperature reactors.

Nuclear Sector: Components used in nuclear reactors requiring high strength and stability.

Fasteners and Springs: Used in environments requiring resistance to high temperatures and fatigue.

Why Choose Hangbo Alloy Group?

Hangbo Alloy Group combines exceptional quality control with an extensive range of product offerings to meet the exacting demands of our customers. Our Nimonic 80A products are manufactured to international standards and can be customized to fit your specific needs. Contact us today to explore how Nimonic 80A can elevate the performance of your critical applications.