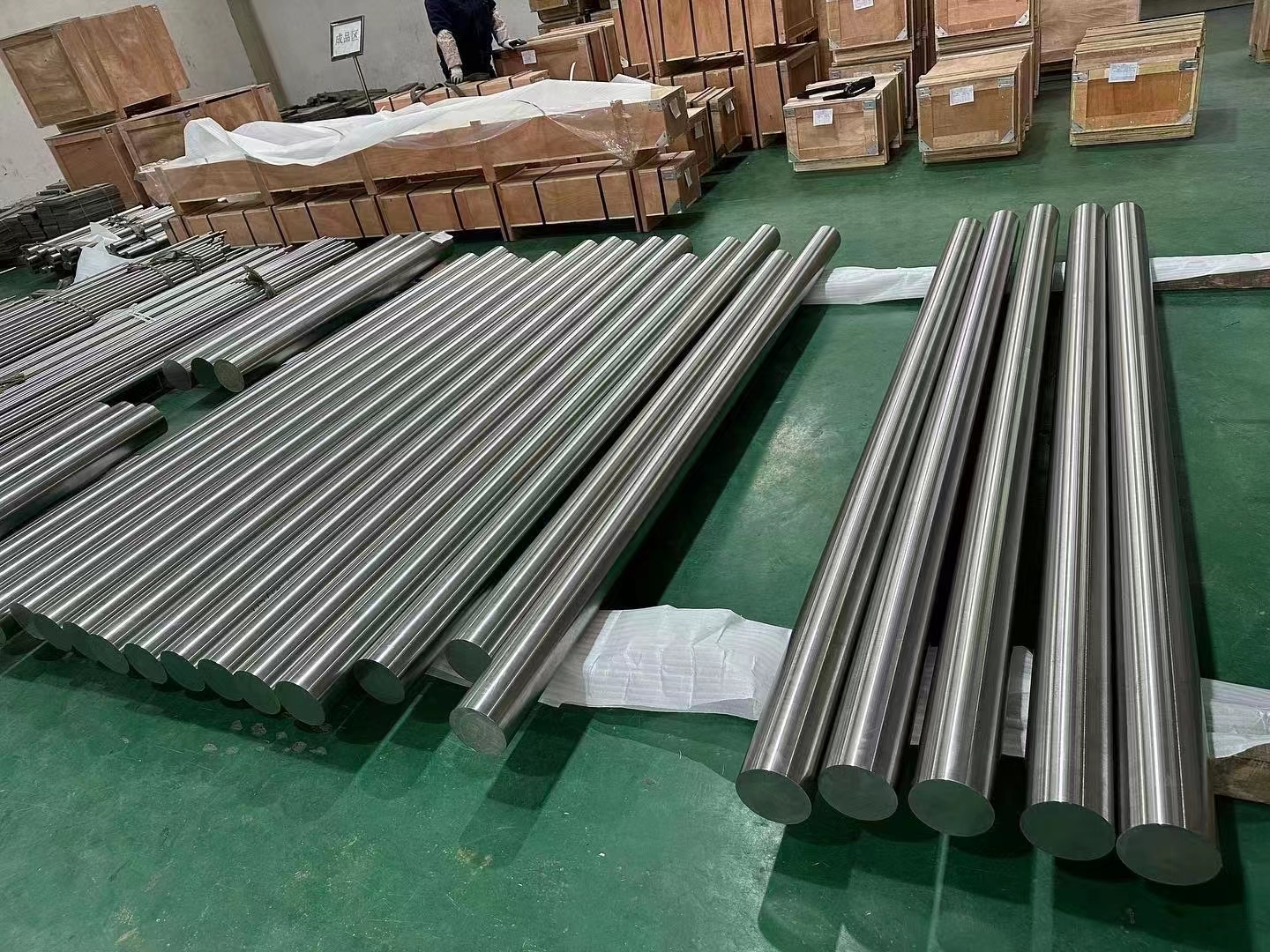

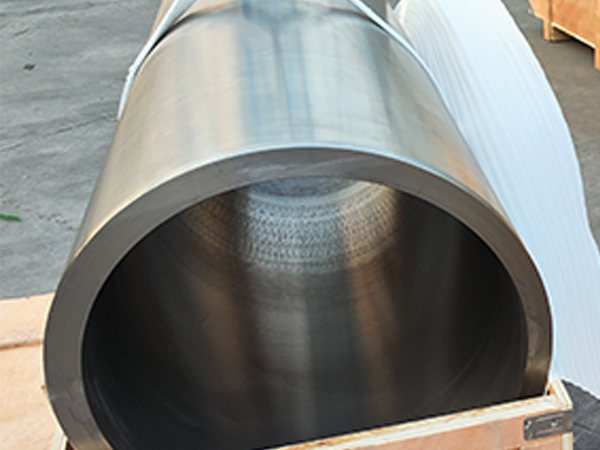

Hangbo Alloy Group proudly supplies a wide range of high-performance alloys in various forms, including round bars, plates, strips, seamless pipes, forgings, and wires. Among these, Nimonic 90 stands out as a premium nickel-based superalloy known for its exceptional strength, thermal stability, and oxidation resistance.

Nimonic 90 is specifically designed for use in high-temperature environments where long-term stress rupture resistance and excellent mechanical properties are critical. This alloy is age-hardenable and features added cobalt and titanium for superior performance in demanding applications.

Equivalent Designations in Different Standards

| Standard | Equivalent Designation |

|---|---|

| UNS | N07090 |

| W.Nr (Germany) | 2.4632 |

| ISO | NiCr20Co18Ti |

| CHINA | GH4090 |

Product Forms and Standards

At Hangbo Alloy Group, Nimonic 90 is available in a variety of forms that adhere to internationally recognized standards.

Chemical Composition of Nimonic 90

The chemical composition of Nimonic 90 is meticulously optimized for excellent high-temperature strength and corrosion resistance. Below is the detailed breakdown:

| Element | Composition (% by weight) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 18.0 - 21.0 |

| Cobalt (Co) | 15.0 - 21.0 |

| Titanium (Ti) | 2.0 - 3.0 |

| Aluminum (Al) | 1.0 – 2.0 |

| Iron (Fe) | ≤1.5 |

| Carbon (C) | ≤0.13 |

| Manganese (Mn) | ≤1.0 |

| (Zr) | ≤0.150 |

| Silicon (Si) | ≤1.0 |

| Boron (B) | ≤0.020 |

| Copper (Cu) | ≤0.20 |

| (P) | ≤0.020 |

| Sulfur (S) | ≤0.015 |

Physical Properties of Nimonic 90

| Property | Value |

|---|---|

| Density | 8.18 g/cm³ |

| Melting Point | 1325°C – 1370°C |

Key Characteristics of Nimonic 90

High-Temperature Strength: Exceptional tensile strength and stress rupture resistance at temperatures up to 920°C.

Oxidation Resistance: Maintains performance and resists scaling in high-temperature oxidative environments.

Age-Hardenable: Improved mechanical properties through heat treatment.

Thermal Stability: Enhanced stability under prolonged high-temperature exposure.

Corrosion Resistance: Performs well in mildly corrosive and high-stress environments.

Machinability and Fabrication: Can be readily machined and fabricated with appropriate tools and techniques.

Applications of Nimonic 90

Nimonic 90’s outstanding properties make it a preferred material in numerous high-performance applications, including:

Aerospace Industry: Turbine blades, discs, and combustion chamber components in jet engines.

Power Generation: Components for steam and gas turbines, including blades and seals.

Automotive Industry: High-performance exhaust valves.

Chemical Processing: Heat exchangers and reactor components for high-temperature operations.

Nuclear Sector: Components for reactors requiring superior high-temperature strength and stability.

Fasteners and Springs: High-stress, high-temperature-resistant bolts, screws, and springs.

Industrial Furnaces: Parts exposed to extreme heat and oxidative environments.

Why Choose Hangbo Alloy Group?

Hangbo Alloy Group is dedicated to delivering premium quality Nimonic 90 products, backed by rigorous quality control, compliance with international standards, and superior customer support. Our extensive inventory, customization options, and technical expertise make us a trusted partner for your high-performance alloyct goals.