Hangbo Alloy Group is a trusted supplier of high-performance alloys, providing products such as round bars, plates, strips, seamless pipes, forgings, and wires. Among our portfolio, Nimonic 75 stands out as a versatile nickel-chromium-based alloy renowned for its excellent oxidation resistance and mechanical properties at elevated temperatures.

Nimonic 75 was initially developed for gas turbine components and has since found extensive applications in various high-temperature environments. Its combination of strength, stability, and oxidation resistance has made it a preferred choice across multiple industries.

Equivalent Designations in Different Standards

| Standard | Equivalent Designation |

|---|---|

| UNS | N06075 |

| W.Nr (Germany) | 2.4951 |

| ISO | NiCr20Ti |

| ASTM | Alloy75 |

| BS (UK) | HR5 |

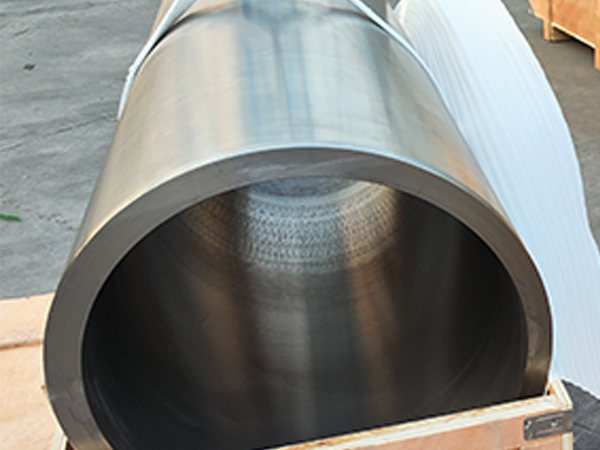

Product Forms and Standards

At Hangbo Alloy Group, Nimonic 75 is available in a variety of forms, each conforming to strict international standards for quality and performance.

Chemical Composition of Nimonic 75

Nimonic 75’s composition ensures a balance of high-temperature strength, oxidation resistance, and stability. The table below provides the detailed chemical composition of this alloy:

| Element | Composition (% by weight) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 18.0 - 21.0 |

| Titanium (Ti) | 0.2 - 0.6 |

| Carbon (C) | 0.08 - 0.15 |

| Iron (Fe) | ≤5.0 |

| Manganese (Mn) | ≤1.0 |

| Silicon (Si) | ≤1.0 |

| Copper (Cu) | ≤0.5 |

Physical Properties of Nimonic 75

| Property | Value |

|---|---|

| Density | 8.37 g/cm³ |

| Melting Point | 1340°C – 1380°C |

Key Characteristics of Nimonic 75

High Oxidation Resistance: Nimonic 75 maintains excellent oxidation resistance at temperatures up to 1000°C.

Stable Mechanical Properties: Its high chromium content ensures strength and stability under cyclic loading and high-temperature conditions.

Ease of Fabrication: The alloy offers excellent weldability, machinability, and formability, making it suitable for complex designs.

Corrosion Resistance: While optimized for oxidation resistance, it also performs well in mildly corrosive environments.

Thermal Stability: The titanium content enhances its ability to withstand thermal cycling without loss of properties.

Applications of Nimonic 75

Thanks to its exceptional properties, Nimonic 75 is used in a wide range of demanding applications, including:

Aerospace Industry: Gas turbine components such as combustion chambers and exhaust systems.

Power Generation: Steam turbines and industrial furnace components.

Chemical Processing: Heat exchangers and high-temperature reactors.

Automotive Industry: High-temperature fasteners and exhaust valves.

Nuclear Sector: Components in nuclear reactors and heat shields.

Why Choose Hangbo Alloy Group?

At Hangbo Alloy Group, we pride ourselves on delivering premium-grade Nimonic 75 products backed by stringent quality control, international standards compliance, and exceptional customer service. Contact us today to learn more about how Nimonic 75 can enhance your project’s performance and reliability.