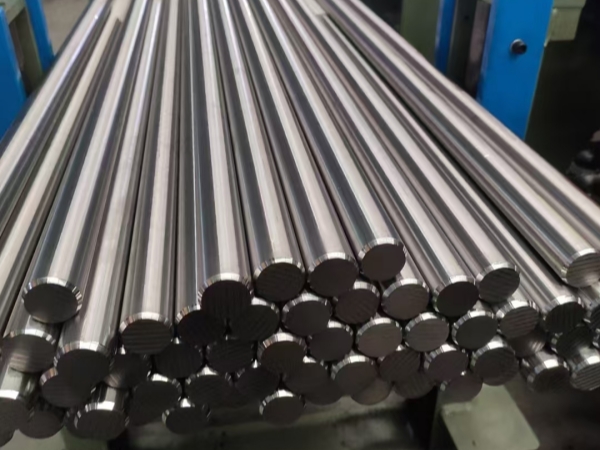

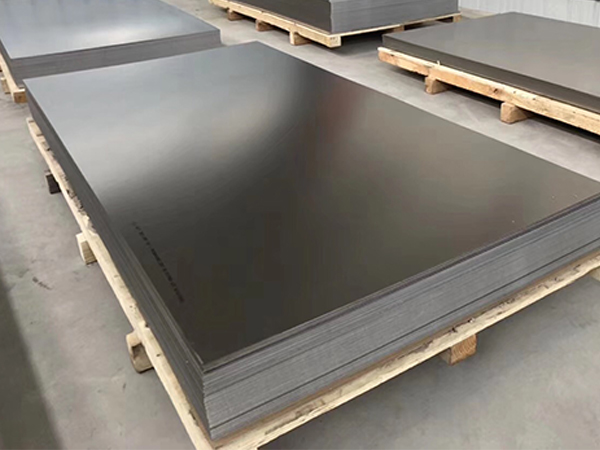

Hangbo Alloy Group offers a diverse range of materials, including round bars, steel plates, strips, seamless pipes, forged products, and wire.

Detailed Introduction to Hastelloy B-2

Hastelloy B-2(UNS N10665) is a nickel-molybdenum alloy renowned for its outstanding resistance to hydrochloric acid at all concentrations and temperatures. It is particularly effective in environments where both reducing and oxidizing conditions are present, making it suitable for a variety of corrosive environments.

The alloy exhibits excellent corrosion resistance against other non-oxidizing acids, such as sulfuric acid and phosphoric acid. Its high molybdenum content contributes to its enhanced performance in these aggressive environments.

Equivalent Grades by Country:

•ASTM: UNS N10665

•DIN: NiMo28

•GB/T: NS3203

International Standards for Hastelloy B-2 Products

The following table outlines the applicable standards for Hastelloy B-2 in various forms:

| Product Form | ASTM Standard |

|---|---|

| Plate,Sheet&Strip | ASTM B333 |

| Round Bar | ASTM B335 |

| Seamless Pipe&Tube | ASTM B622 |

| Welded Pipe&Tube | ASTM B619,ASTM B626 |

ForgingASTM B564,ASTM B462FittingsASTM B366

Chemical Composition of Hastelloy B-2

The chemical composition of Hastelloy B-2 is summarized in the following table:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 65.0 - 74.0 |

| Molybdenum (Mo) | 26.0 - 30.0 |

| Iron (Fe) | ≤ 2.0 |

| Chromium (Cr) | ≤ 1.0 |

| Carbon (C) | ≤ 0.02 |

| Silicon (Si) | ≤ 0.10 |

| Manganese (Mn) | ≤ 1.00 |

| Cobalt(Co) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

Physical Properties of Hastelloy B-2

Key physical properties of Hastelloy B-2 are outlined in the table below:

| Property | Value |

|---|---|

| Density | 8.9 g/cm³ |

| Melting Point | 1330 - 1380 °C |

Material Characteristics

Hastelloy B-2 is characterized by several key properties:

• Corrosion Resistance: Exceptional resistance to hydrochloric acid and other non-oxidizing acids.

• High Strength: Maintains strength in high-temperature environments.

• Weldability: Can be easily welded using standard techniques, facilitating fabrication.

• Versatility: Effective in both reducing and oxidizing environments.

Applications of Hastelloy B-2

Hastelloy B-2 is utilized across various industries, including:

• Chemical Processing: Equipment such as reactors and heat exchangers that handle corrosive chemicals.

• Oil and Gas: Components exposed to corrosive environments during extraction and processing.

• Pharmaceuticals: Equipment for manufacturing processes involving harsh chemicals.

• Environmental: Systems for waste treatment that require high resistance to aggressive media.