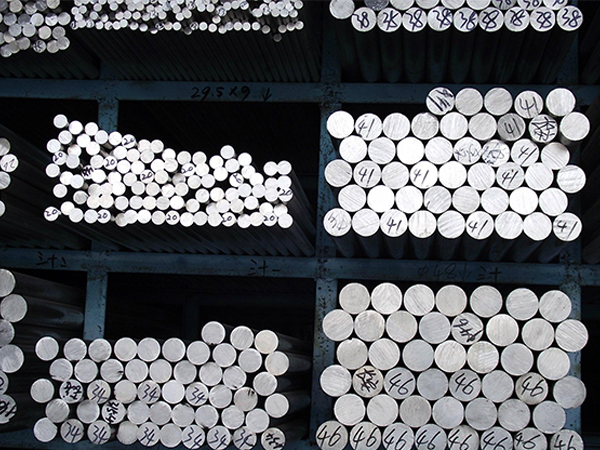

Hangbo Alloy Group supplies a comprehensive range of MONEL K500 alloy products, including round bars, plates, strips, seamless tubes, forgings, and wires. Below is a detailed product description of MONEL K500.

1. Introduction to MONEL K500

Description: MONEL K500 (UNS N05500) is a nickel-copper alloy known for combining the corrosion resistance of MONEL 400 with increased strength and hardness due to added aluminum and titanium, which allow for age-hardening. MONEL K500 maintains durability and corrosion resistance across a wide range of temperatures.

International Equivalents:

USA: UNS N05500

Europe: DIN 2.4375

China: GB/T 19228

Aerospace: AMS 4676, AMS 4675

2. Standards for MONEL K500 Products

Plates: ASTM B127, AMS 4676

Round Bars: ASTM B865, AMS 4675

Seamless Tubes: ASTM B165, DIN 2.4375

Forgings: ASTM B564, DIN 2.4375

3. Chemical Composition of MONEL K500 (in %)

| Element | Content (%) |

|---|---|

| Nickel (Ni) | ≥63.0 |

| Copper (Cu) | 27.0 - 33.0 |

| Aluminum (Al) | 2.30 - 3.15 |

| Titanium (Ti) | 0.35 - 0.85 |

| Iron (Fe) | ≤ 2.00 |

| Manganese (Mn) | ≤ 1.50 |

| Carbon (C) | ≤ 0.18 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.010 |

4. Physical Properties of MONEL K500

| Property | Value |

|---|---|

| Density | 8.47 g/cm³ |

| Melting Range | 1300 - 1350 °C |

5. Material Characteristics of MONEL K500

Corrosion Resistance: Exceptional resistance to seawater, sour gas, and acidic and alkaline environments. MONEL K500 is also highly resistant to cavitation and stress corrosion.

High Strength: Precipitation-hardened, MONEL K500 is substantially stronger than MONEL 400, making it suitable for high-stress applications.

Temperature Stability: Maintains strength and toughness from cryogenic temperatures up to around 480 °C.

Non-Magnetic: Retains non-magnetic properties, even after prolonged use in sub-zero conditions.

6. Applications of MONEL K500

Marine Engineering: Used in shafts, pump and valve components, and propeller blades in seawater systems.

Oil and Gas Industry: Ideal for sour gas applications, valve trim, and other high-strength applications in challenging environments.

Chemical Processing: Employed in corrosive applications, such as heat exchangers and processing equipment.

Aerospace: Components requiring high strength and durability, including landing gear and turbine blades.

Medical Equipment: Parts that need high resistance to corrosion and non-magnetic properties.