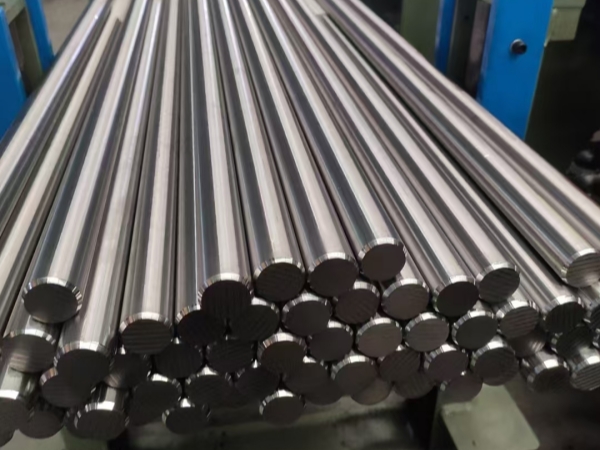

Hangbo Alloy Group offers a diverse range of materials, including round bars, steel plates, strips, seamless pipes, forged products, and wire. Below is a detailed overview of HASTELLOY C-276:

Detailed Introduction to Hastelloy C-276

Hastelloy C-276(UNS N10276) is a nickel-molybdenum-chromium superalloy that exhibits exceptional corrosion resistance and is ideal for harsh environments. It is particularly well-suited for applications that involve exposure to a variety of corrosive media, including acids, saltwater, and industrial chemicals.

This alloy maintains its mechanical properties at high temperatures and is renowned for its ability to resist pitting, crevice corrosion, and stress corrosion cracking. Its unique composition ensures durability and reliability across many applications.

Equivalent Grades by Country:

• ASTM: UNS N10276

• DIN: NiMo16Cr15W W.Nr.2.4819

International Standards for Hastelloy C-276 Products

The following table outlines the applicable standards for Hastelloy C-276 in various forms:

| Product Form | ASTM Standard |

|---|---|

| Plate,Sheet&Strip | ASTM B575 |

| Round Bar | ASTM B574 |

| Seamless Pipe&Tube | ASTM B622, ASTM B983 |

| Welded Pipe&Tube | ASTM B619, ASTM B626 |

| Forging | ASTM B564, ASTM B462 |

Chemical Composition of Hastelloy C-276

The chemical composition of Hastelloy C-276 is summarized in the following table:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 51.0 - 63.5 |

| Molybdenum (Mo) | 15.0 - 17.0 |

| Chromium (Cr) | 14.5 - 16.5 |

| Iron (Fe) | 4.0 - 7.0 |

| Tungsten (W) | 3.0 - 4.5 |

| Cobalt(Co) | ≤ 2.50 |

| Carbon (C) | ≤ 0.02 |

| Silicon (Si) | ≤ 0.08 |

| Manganese (Mn) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

| Vanadium(V) | ≤ 0.35 |

Physical Properties of Hastelloy C-276

Key physical properties of Hastelloy C-276 are outlined in the table below:

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ |

| Melting Point | 1323 - 1371 °C |

Material Characteristics

Hastelloy C-276 is characterized by several key properties:

• Corrosion Resistance: Outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking in diverse environments.

• High Strength: Maintains mechanical strength in high-temperature settings and corrosive conditions.

• Weldability: Can be easily welded using standard techniques, facilitating fabrication.

• Ductility: Excellent ductility allows for extensive forming and fabrication.

Applications of Hastelloy C-276

Hastelloy C-276 is utilized across various industries, including:

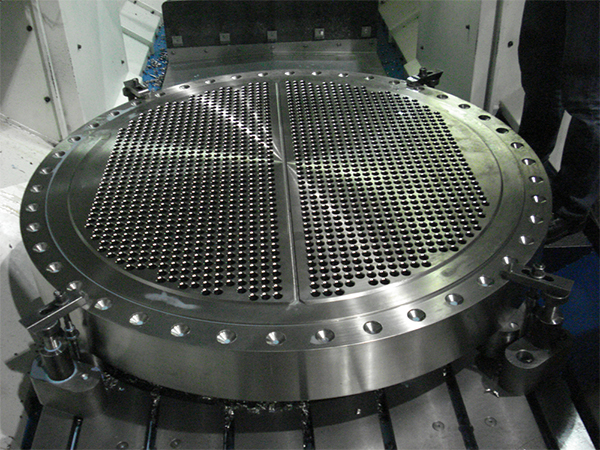

• Chemical Processing: Equipment such as reactors, heat exchangers, and pipelines that handle corrosive substances.

• Oil and Gas: Components used in downhole and surface equipment in oil extraction.

• Power Generation: Parts used in fossil fuel and nuclear plants requiring corrosion resistance.

• Pharmaceuticals: Equipment for processing reactive and corrosive chemical compounds.

• Environmental: Systems for flue gas desulfurization and waste treatment processes.