Detailed Introduction to Hastelloy X

Hastelloy X is a high-performance nickel-chromium-molybdenum alloy that is known for its exceptional resistance to oxidation and high-temperature corrosion, making it ideal for use in extreme environments such as gas turbines, aircraft engines, and other high-temperature applications. This alloy is widely used in the aerospace and chemical industries due to its excellent mechanical properties at elevated temperatures.

Main Properties:

- Excellent oxidation and carburization resistance up to 2200°F (1204°C).

- Good weldability and fabricability.

- High strength and oxidation resistance at elevated temperatures.

- It is resistant to many forms of degradation such as stress-corrosion cracking, pitting, and crevice corrosion.

International Alloy Numbering System (or Corresponding Alloys):

Hastelloy X is known by various names in different countries and standards:

- ASTM: N06002 (Universal Numbering System)

- DIN: W.Nr. 2.4665

- GB/T: GH3536

Hastelloy X Product Standards

The following table outlines the applicable standards for Hastelloy X in various forms:

| Product Form | Standard |

|---|---|

| Plate,Sheet&Strip | ASTM B435SAE AMS 5536 |

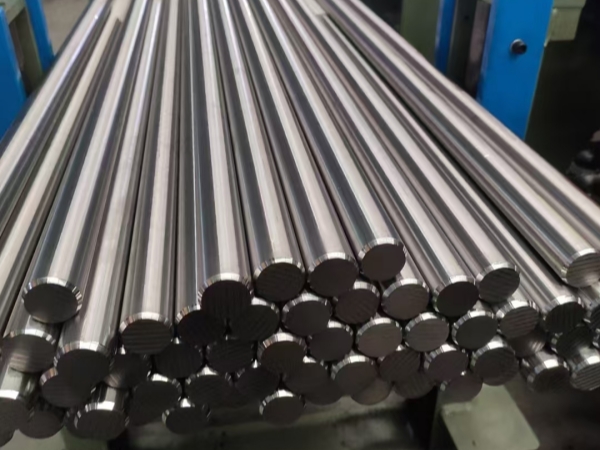

| Round Bar | ASTM B472, ASTM B572 |

| Seamless Pipe&Tube | ASTM B622 |

| Welded Pipe&Tube | ASTM B619, ASTM B626 |

| Forging | SAE AMS 5754 |

| Fittings | ASTM B366 |

Chemical Composition of Hastelloy X

The chemical composition of Hastelloy X is summarized in the following table:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 41.3-53.7 |

| Chromium (Cr) | 20.5-23.0 |

| Molybdenum (Mo) | 8.0-10.0 |

| Iron (Fe) | 17.0-20.0 |

| Cobalt(Co) | 0.50-2.50 |

| Tungsten(W) | 0.2-1.0 |

| Alumiun(Al) | ≤ 0.50 |

| Titanium(Ti) | ≤ 0.15 |

| Boron(B) | ≤ 0.008 |

| Carbon (C) | 0.05-0.15 |

| Silicon (Si) | ≤1.00 |

| Manganese (Mn) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

Physical Properties of Hastelloy X

Here is the table summarizing the density and melting point of Hastelloy X:

| Property | Value |

|---|---|

| Density | 8.22 g/cm³ |

| Melting Point | 1260 - 1355 °C |

Material Characteristics of Hastelloy X

• High-Temperature Strength: Excellent mechanical strength at high temperatures (up to 2200°F or 1200°C), making it ideal for high-stress applications like gas turbines and engines.

• Oxidation Resistance: The alloy resists oxidation up to 2200°F, making it suitable for use in harsh environments.

• Corrosion Resistance: Outstanding resistance to carburization and sulfidation, especially in reducing environments.

• Weldability: Easily weldable using conventional welding methods such as TIG, MIG, and resistance welding.

• Fabricability: The alloy can be hot or cold worked, allowing flexibility in manufacturing parts with different geometries.

Applications of Hastelloy X

Hastelloy X is used across a variety of industries and applications that demand high temperature and corrosion-resistant materials, including:

• Aerospace Industry: Aircraft engines, especially in turbine and combustion sections. Exhaust systems for aerospace applications.

• Gas Turbines: Components like turbine blades, vanes, and combustion chambers.

• Chemical Processing: Reactor components and parts exposed to high temperatures and reactive gases.

• Nuclear Applications: Parts exposed to high radiation or extreme thermal conditions.

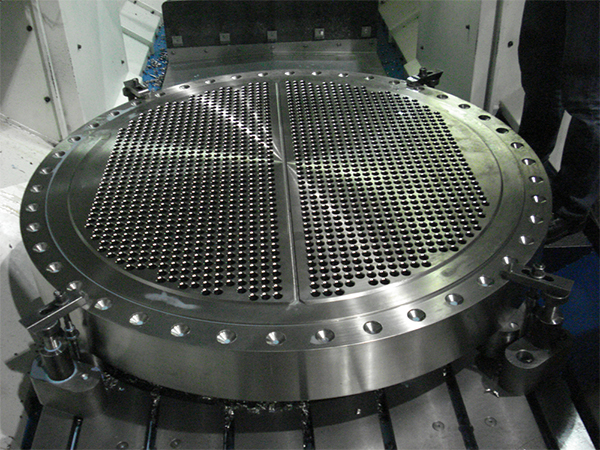

• Heat Exchangers: Used in heat exchangers exposed to both high temperatures and corrosive fluids.

• Power Generation: Critical components in high-efficiency power plants that require long-term reliability under high-temperature conditions.

• Superalloy Applications: Used as a superalloy in environments where resistance to oxidation and mechanical strength at high temperatures are essential.