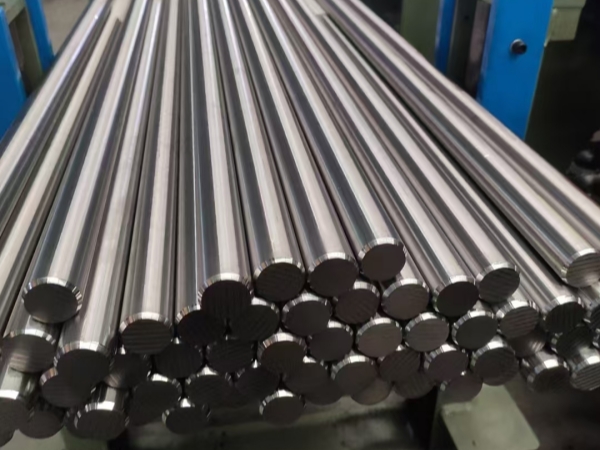

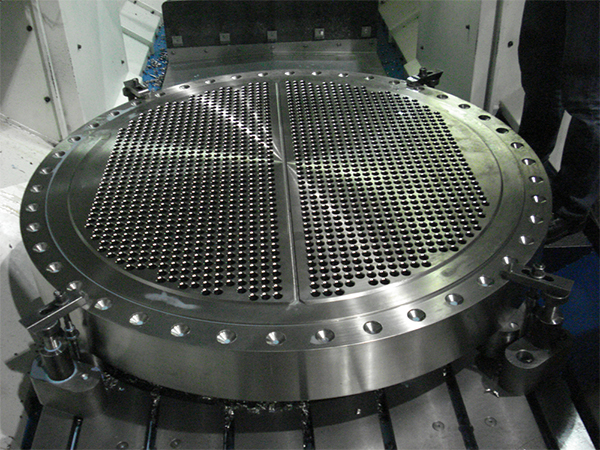

Hangbo Alloy Group offers a diverse range of materials, including round bars, steel plates, strips, seamless pipes, forged products, and wire. Below is a comprehensive overview of HASTELLOY G3:

Introduction to Hastelloy G3

Hastelloy G3 is a nickel-chromium-molybdenum-iron alloy specifically designed to deliver exceptional resistance to both oxidizing and reducing corrosive environments. This alloy stands out for its superior resistance to pitting, crevice corrosion, and stress corrosion cracking, even in harsh media containing chloride ions, sulfuric acid, and phosphoric acid—making it ideal for applications involving highly aggressive chemicals.

Equivalent Grades by Country:

USA: UNS N06985

DIN: NiCr21Mo14W (2.4619)

International Standards for Hastelloy G3 Products

Plate, Sheet & Strip:ASTM B575, ASME SB-575

Round Bar:ASTM B574, ASME SB-574

Seamless Pipe & Tube:ASTM B622, ASME SB-622

Welded Pipe & Tube:ASTM B619, ASTM B626, ASME SB-619, ASME SB-626

Forging:ASTM B462, ASME SB-462

Fittings:ASTM B366, ASME SB-366; ASTM B462, ASME SB-462

Chemical Composition of Hastelloy G3

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 36.9-45.4 |

| Chromium (Cr) | 21.0 - 23.5 |

| Molybdenum (Mo) | 6.0-8.0 |

| Iron (Fe) | 18.0-21.0 |

| Tungsten (W) | ≤ 1.50 |

| Cobalt (Co) | ≤ 5.00 |

| Copper (Cu) | 1.50-2.50 |

| Columbium(Nb)+Tantalum(Ta) | ≤ 0.50 |

| Carbon (C) | ≤ 0.015 |

| Silicon (Si) | ≤ 1.00 |

| Manganese (Mn) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

Physical Properties of Hastelloy G3

| Property | Value |

|---|---|

| Density | 8.20 g/cm³ |

| Melting Point | 1330 - 1380 °C |

Material Characteristics

Dual-Environment Corrosion Resistance: Excels in both oxidizing (e.g., nitric acid, hypochlorite solutions) and reducing (e.g., sulfuric acid, hydrochloric acid) environments, with strong resistance to chloride-induced pitting and crevice corrosion—ideal for mixed-acid process streams.

High-Temperature Stability: Maintains excellent mechanical strength and corrosion resistance at elevated temperatures (up to 1040°C), suitable for high-heat industrial applications like furnace components and heat exchangers.

Superior Weldability: Compatible with common welding processes (TIG, MIG, SMAW) without requiring pre-heating; welded joints retain high corrosion resistance and mechanical strength, avoiding post-weld cracking risks.

Good Fabricability: Easily processed via cold rolling, forging, and machining (with appropriate tooling); post-fabrication heat treatment (e.g., annealing at 1150 - 1180°C followed by rapid cooling) optimizes its corrosion resistance and ductility.

Applications of Hastelloy G3

Chemical Processing: Equipment such as reactors, heat exchangers, and storage tanks for handling mixed acids (e.g., sulfuric-nitric acid blends), phosphoric acid, and chloride-containing solutions.

Pharmaceuticals: Stainless steel-compatible machinery (e.g., mixing vessels, transfer pipes) for drug synthesis, where high purity and resistance to organic/inorganic corrosive reagents are critical.

Oil and Gas: Downhole tools, wellhead components, and pipeline systems for sour gas (containing hydrogen sulfide) and high-chloride brine environments, ensuring long-term service in offshore and onshore extraction.

Environmental Technologies: Components for flue gas desulfurization (FGD) systems, wastewater treatment equipment, and landfill leachate processing units—resisting corrosion from acidic and chloride-rich waste streams.

Mining and Metallurgy: Acid leaching tanks, electrolytic cells, and slurry pumps for mineral processing (e.g., copper, nickel extraction), where aggressive acidic media and solid particle erosion are common.