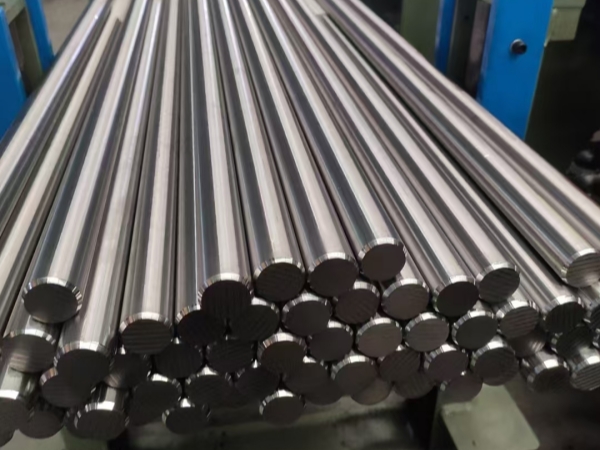

Hangbo Alloy Group offers a diverse range of materials, including round bars, steel plates, strips, seamless pipes, forged products, and wire. Below is a comprehensive overview of HASTELLOY G-35:

Detailed Introduction to Hastelloy G-35

Hastelloy G-35 is a nickel-chromium-molybdenum alloy specifically designed to offer outstanding resistance to a variety of corrosive environments, particularly in oxidizing conditions. This alloy is particularly effective against pitting and stress corrosion cracking, making it ideal for applications that involve aggressive chemicals.

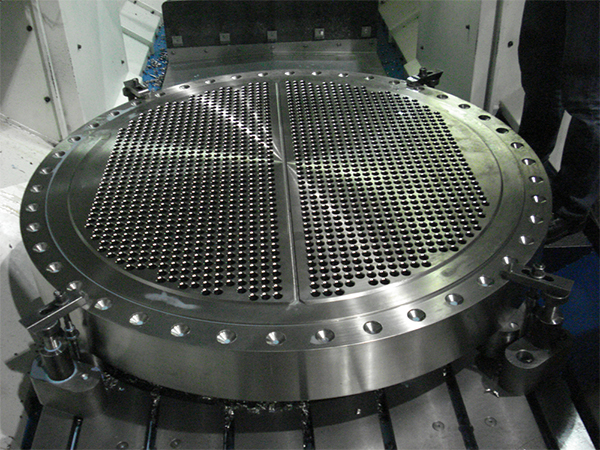

Hastelloy G-35 features excellent weldability and formability, allowing it to be fabricated into complex shapes for various industrial applications. Its versatility and reliability make it a preferred choice in environments with high temperatures and corrosive substances.

Equivalent Grades by Country:

• ASTM: UNS N06035

• DIN: NiCrMo-8

International Standards for Hastelloy G-35 Products

The following table outlines the applicable standards for Hastelloy G-35 in various forms:

| Product Form | ASTM Standard |

|---|---|

| Plate,Sheet&Strip | ASTM B575 |

| Round Bar | ASTM B574 |

| Seamless Pipe&Tube | ASTM B622 |

| Welded Pipe&Tube | ASTM B619, ASTM B626 |

| Forging | ASTM B462 |

| Fittings | ASTM B366, ASTM B462 |

Chemical Composition of Hastelloy G-35

The chemical composition of Hastelloy G-35 is summarized in the following table:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Bal |

| Chromium (Cr) | 32.25-34.25 |

| Molybdenum (Mo) | 7.6-9.0 |

| Iron (Fe) | ≤ 2.0 |

| Cobalt(Co) | ≤1.00 |

| Tungsten(W) | ≤ 0.60 |

| Alumiun(Al) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.30 |

| Vanadium(V) | ≤ 0.20 |

| Carbon (C) | ≤ 0.05 |

| Silicon (Si) | ≤ 0.60 |

| Manganese (Mn) | ≤ 0.50 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.015 |

Physical Properties of Hastelloy G-35

Key physical properties of Hastelloy G-35 are outlined in the table below:

| Property | Value |

|---|---|

| Density | 8.22 g/cm³ |

| Melting Point | 1332- 1361°C |

Material Characteristics

Hastelloy G-35 is characterized by several key properties:

• Corrosion Resistance: Excellent resistance to localized corrosion, particularly in oxidizing environments.

• High-Temperature Strength: Maintains mechanical integrity at elevated temperatures.

• Weldability: Suitable for various welding processes, ensuring strong and durable joints.

• Fabricability: Easily formed and machined, making it versatile for different applications.

Applications of Hastelloy G-35

Hastelloy G-35 is utilized across several industries, including:

• Chemical Processing: Equipment handling strong oxidizing acids and corrosive materials.

• Pharmaceuticals: Machinery used in the production of drugs that require high purity and corrosion resistance.

• Oil and Gas: Components for upstream and downstream processes where corrosion resistance is crucial.

• Environmental Technologies: Applications in waste treatment and pollution control systems.