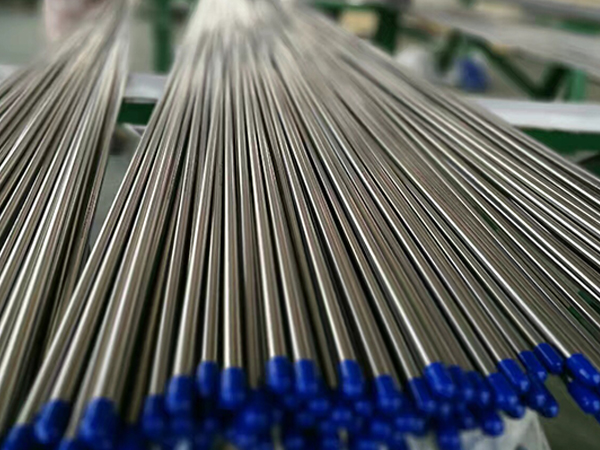

Hangbo Alloy Group supplies a variety of materials, including round bars, plates, strips, seamless pipes, forged products, and wire. Below is a comprehensive description of Incoloy 330.

Incoloy 330 Detailed Introduction

INCOLOY® alloy 330 (UNS N08330 / W. Nr. 1.4886) is an austenitic alloy with good high-temperature strength and corrosion resistance. It has a solid solution composition and is not hardenable by heat treatment. Its high nickel and chromium provide good resistance to oxidation and carburization. Its oxidation resistance is enhanced by the silicon content.

| Standard | Equivalent Grade |

|---|---|

| ASTM | UNS N08330 |

| DIN | W.Nr.1.4886 |

Incoloy 330 Standards for Products

| Product Form | Standards |

|---|---|

| Plates/Sheets | ASTM B53, SAE AMS 55926 |

| Round Bars | ASTM B511, SAE AMS 5716 |

| Seamless Pipes | ASTM B535, ASTM B829 |

| Welded Pipes | ASTM B710 |

| Welded Tube | ASTM B739 |

| Forgings | SAE AMS 5716 |

Incoloy 330 Chemical Composition

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 34.0 - 37.0 |

| Chromium (Cr) | 17.0 - 20.0 |

| Iron (Fe) | Bal. |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | 0.75 - 1.50 |

| Sulfur (S) | ≤ 0.030 |

| Phosphorus(P) | ≤ 0.030 |

| Copper(Cu) | ≤ 1.00 |

Incoloy 330 Physical Properties

| Property | Value |

|---|---|

| Density | 8.08 g/cm³ |

| Melting Point | 1380 - 1420 °C |

Incoloy 330 Material Characteristics

• Excellent high-temperature strength and oxidation resistance.

• Good resistance to carburization and sulfidation.

• High ductility and weldability, suitable for various fabrication methods.

• Reliable performance in aggressive environments, making it suitable for demanding applications.

Applications of Incoloy 330

• Industrial furnace applications, including heating elements and radiant tubes.

• Components in petrochemical processing.

• Equipment in thermal processing and heat treatment.

• Applications requiring resistance to high temperatures and corrosive atmospheres.