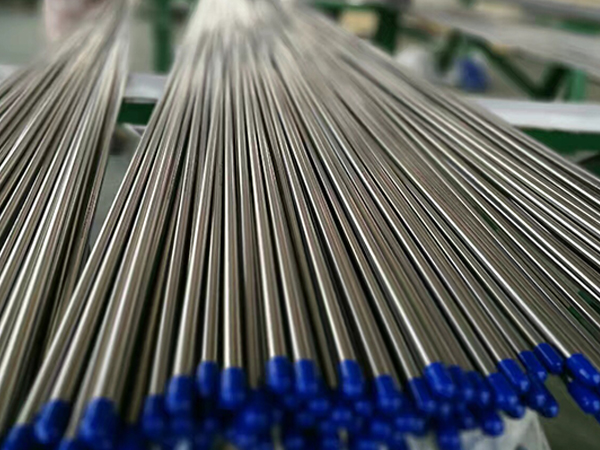

Hangbo Alloy Group supplies a variety of materials, including round bars, plates, strips, seamless pipes, forged products, and wire. Below is a comprehensive description of Incoloy 800HT.

Incoloy 800HT Detailed Introduction

INCOLOY 800HT(UNS N08811) alloys belong to the category of super austenitic stainless steels. These alloys have nickel-chromium-iron as the base metals, with additives such as molybdenum, copper, nitrogen and silicon. These alloys are known for their excellent strength at elevated temperatures and good corrosion resistance in a variety of corrosive environments.

| Standard | Equivalent Grade |

|---|---|

| ASTM | UNS N08811 |

| DIN | W.Nr.1.4959 |

Incoloy 800HT Standards for Products

| Product Form | ASTM Standards |

|---|---|

| Plates/Sheets | ASTM B409 |

| Round Bars | ASTM B408 |

| Seamless Pipes | ASTM B407 |

| Welded Tube | ASTM B515 |

| Forgings | ASTM B564 |

Incoloy 800HT Chemical Composition

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 30.0 - 35.0 |

| Chromium (Cr) | 19.0 - 23.0 |

| Iron (Fe) | ≥39.5 |

| Carbon (C) | 0.06-0.10 |

| Manganese (Mn) | ≤ 1.50 |

| Silicon (Si) | ≤ 1.00 |

| Sulfur (S) | ≤ 0.015 |

| Titanium (Ti) | 0.15 - 0.60 |

| Copper (Cu) | ≤ 0.75 |

| Aluminum (Al) | 0.15 - 0.60 |

Incoloy 800HT Physical Properties

| Property | Value |

|---|---|

| Density | 8.0 g/cm³ |

| Melting Point | 1357 - 1385 °C |

Incoloy 800HT Material Characteristics

• Exceptional resistance to oxidation and carburization.

• High strength and stability at elevated temperatures, particularly suited for higher thermal stress applications.

• Good weldability and formability.

• Enhanced creep resistance compared to standard Incoloy 800.

Applications of Incoloy 800HT

• Components in heat exchangers and reactors in petrochemical processing.

• Applications in furnace construction, including tubes and baffles.

• Oil and gas industry equipment requiring high-temperature strength.

• Power generation components, such as superheaters and boiler tubes.