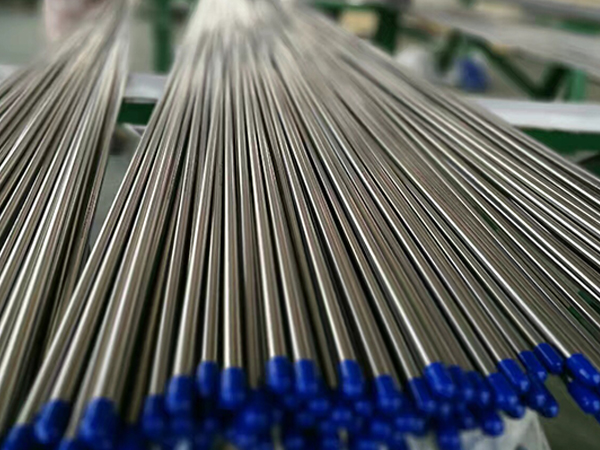

Hangbo Alloy Group supplies a variety of materials, including round bars, plates, strips, seamless pipes, forged products, and wire. Below is a comprehensive description of Incoloy A286.

Incoloy A286 Detailed Introduction

INCOLOY® alloy A-286 (UNS S66286 / W.Nr. 1.4980) is an iron-nickel-chromium alloy with additions of molybdenum and titanium. It is agehardenable for high mechanical properties. The alloy maintains good strength and oxidation resistance at temperatures up to about 1300°F (700°C). The alloy is austenitic in all metallurgical conditions.

The high strength and excellent fabrication characteristics of INCOLOY alloy A-286 make the alloy useful for various components of aircraft and industrial gas turbines. It is also used for fastener applications in automotive engine and manifold components subject to high levels of heat and stress and in the offshore oil and gas industry.

| Standard | Equivalent Grade |

|---|---|

| ASTM | UNS S66286 |

| DIN | W.Nr.1.4980 |

Incoloy A286 Standards for Products

| Product Type | ASTM Standard | AMS Standard |

|---|---|---|

| Steel Plate | / | AMS 5525, AMS 5858 |

| Round Bar | / | AMS 5731, AMS 5732 |

| Forging | ASTM A638 | AMS 5525 |

Incoloy A286 Chemical Composition

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 24.0 - 27.0 |

| Chromium (Cr) | 13.5 - 16.0 |

| Iron (Fe) | 49.1-56.0 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Molybdenum(Mo) | 1.00-1.50 |

| Phosphorus(P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Titanium (Ti) | 1.90- 2.35 |

| Aluminum (Al) | ≤ 0.35 |

| Vanadium(V) | 0.10-0.50 |

| Boron(B) | 0.001-0.010 |

Incoloy A286 Physical Properties

| Property | Value |

|---|---|

| Density | 7.94 g/cm³ |

| Melting Point | 1370 - 1430 °C |

Incoloy A286 Material Characteristics

• Excellent high-temperature strength and oxidation resistance.

• Good corrosion resistance in high-stress environments.

• High ductility and formability, allowing for complex shapes and designs.

• Suitable for high-temperature applications, including jet engines and gas turbines.

Applications of Incoloy A286

• Aerospace components, including jet engine parts and combustion chambers.

• Gas turbine engines in power generation.

• Chemical processing equipment that operates under high temperatures and pressures.

• Heat exchangers and structural components in high-temperature environments.