Hangbo Alloy Group supplies a variety of materials, including round bars, plates, strips, seamless pipes, forged products, and wire. Below is a comprehensive description of Incoloy 825.

Incoloy 825 Detailed Introduction

| Standard |

Equivalent Grade |

| ASTM |

UNS N08825 |

| DIN |

W.Nr.2.4858, NiCr21Mo |

| GB |

NS1402 |

| BS |

NA16 |

| AFNOR |

NC21FEDU |

Incoloy 825 Standards for Products

| Product Form |

ASTM Standards |

| Plates/Sheets |

ASTM B424 |

| Round Bars |

ASTM B425 |

| Seamless Pipes |

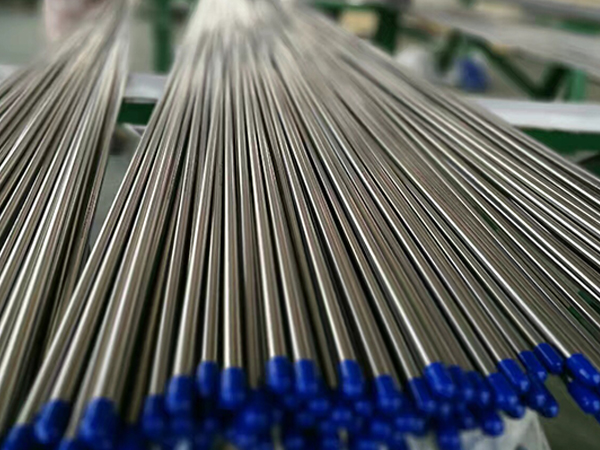

ASTM B423 |

| Welded Pipes |

ASTM B163 |

| Welded Tube |

ASTM B704 |

| Forgings |

ASTM B564 |

Incoloy 825 Chemical Composition

| Element |

Content (%) |

| Nickel (Ni) |

38.0 - 46.0 |

| Chromium (Cr) |

19.5 - 23.5 |

| Molybdenum(Mo) |

2.5 – 3.5 |

| Iron (Fe) |

≥22.0 |

| Carbon (C) |

≤ 0.05 |

| Manganese (Mn) |

≤ 1.00 |

| Silicon (Si) |

≤ 0.50 |

| Sulfur (S) |

≤ 0.030 |

| Copper (Cu) |

1.50 - 3.00 |

| Aluminum (Al) |

≤ 0.20 |

| Titanium (Ti) |

0.60 - 1.20 |

Incoloy 825 Physical Properties

| Property |

Value |

| Density |

8.14 g/cm³ |

| Melting Point |

2500-2550 °C |

Incoloy 825 Material Characteristics

• Excellent resistance to pitting and crevice corrosion.

• Good mechanical properties at both ambient and elevated temperatures.

• High resistance to oxidation and reducing environments.

• Suitable for severe corrosive environments, including acidic and alkaline media.

Applications of Incoloy 825

• Chemical processing equipment, such as reactors and heat exchangers.

• Oil and gas industry applications, including pipelines and valves.

• Waste treatment systems and flue gas desulfurization.

• Marine applications and equipment exposed to seawater.